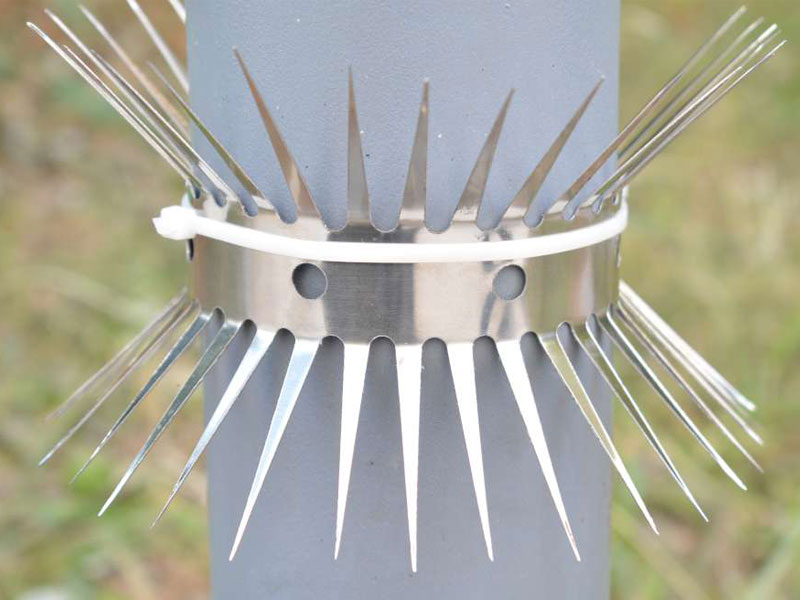

Choose Bird Control Spikes From a Quality Standpoint

Know About the Type of Stainless Steel You are Getting With Your Bird Spikes

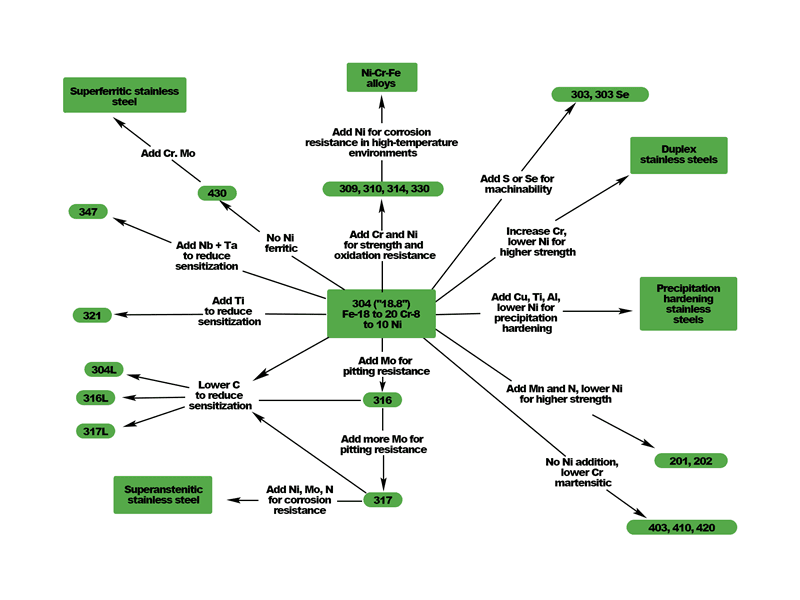

Due to its excellent corrosion resistance, stainless steel has become an important raw material for bird spike products. But you probably don't know that stainless steel can be divided into over 150 grades and 5 families. And they are looked so similar in appearance that you won't able to tell the difference between the quality of your bird spikes.

We'd like to introduce stainless steel from multiple classification dimensions. So as to help you choose a cost effective bird control solution that is sustainable and weather resistant. According to the crystalline structure, stainless steel can be grouped into five main families.

Austenitic Stainless Steel

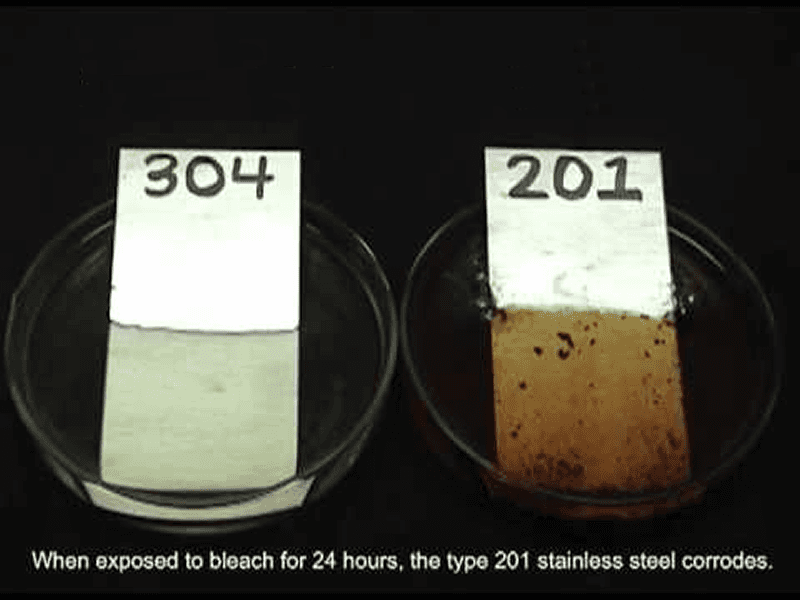

Austenitic stainless steel typically consists of 16% chromium, 7% nickel and nitrogen. It is the largest family of stainless steels and has better corrosion resistance than ferrite and martensite types. Affected by the difference of metallurgical composition, the austenite includes low nickel 200 series and Cr-Ni 300 series.

- 200 series are low nickel stainless steel. Producers maximize the use of manganese and nitrogen to minimize the use of nickel, so it is also known as chromium-manganese-nickel stainless steel. The most common types are 201 and 202.

- 300 series, chromium-nickel alloys, are the most widely used type of stainless steel. It is more resistant to corrosion than the 200 series but costs more. The most famous of these are the type 304 and type 316.

Ferritic Stainless Steel

Ferritic stainless steel, with a ferrite microstructure like carbon steel, consists of 10.5% – 27% chromium and very little or no nickel. Although it is less resistant to corrosion than austenitic stainless steel, still slightly better than martensitic type. The most commonly used for bird spike production is the type 430. These products have the advantage of being relatively cheap.

Martensitic Stainless Steel

Martensitic stainless steel, with high strength and good toughness, is ideally as structural steel for aerospace applications. Compared with the above two types, its corrosion resistance is worse.

Duplex Stainless Steel

Duplex stainless steel has a mixed microstructure of austenite and ferrite. It contains less nickel and is about twice as hard as austenitic stainless steel. It also offers improved resistance to chloride stress corrosion cracking.

Precipitation Hardening Stainless Steel

It is a type of stainless steel with high strength, high toughness and high corrosion resistance by adding hardening elements alone or in combination. The most common type is 17-4PH which uses about 17% chromium and 4% nickel.

Stainless Steel is Not a Single Alloy.

Additions of chromium can increase the corrosion resistance. The content of molybdenum also determines the corrosion resistance in reducing acids and against pitting attack in chloride solutions. Nickel, called an austenitic forming element, is added to improve the plasticity, weldability and toughness of stainless steel. In addition, manganese, titanium, silicon and other elements are also essential in stainless steel.

| 201 | 202 | 430 | 304 | 316 | |

|---|---|---|---|---|---|

| Microstructure | low nickel austenite | low nickel austenite | ferrite | austenite | austenite |

| C (%) | ≤ 0.15 | ≤ 0.15 | ≤ 0.12 | ≤ 0.07 | ≤ 0.08 |

| Si (%) | ≤ 1.00 | ≤ 1.00 | ≤ 0.075 | ≤ 1.00 | ≤ 1.50 |

| Mn (%) | 5.5–7.5 | 7.5–10.0 | ≤ 1.00 | ≤ 2.00 | ≤ 2.00 |

| P (%) | ≤ 0.06 | ≤ 0.06 | ≤ 0.040 | ≤ 0.045 | ≤ 0.045 |

| S (%) | ≤ 0.03 | ≤ 0.03 | ≤ 0.030 | ≤ 0.030 | ≤ 0.030 |

| Cr (%) | 16–18 | 17–19 | 16–18 | 17–19 | 16–18 |

| Ni (%) | 3.5–5.5 | 4.0–6.0 | – | 8.0–11.0 | 10.0–14.0 |

| N (%) | ≤ 0.25 | ≤ 0.25 | – | ≤ 0.11 | – |

| * C: carbon, Si: silicon, Mn: manganese, P: phosphorus, S: sulfur, Cr: chromium, Ni: nickel, N: nitrogen. | |||||

| Type | Tensile Strength | Yield Strength | Elongation | Hardness | Corrosion Resistance | |

|---|---|---|---|---|---|---|

| MPa | MPa | % | HB | HRB | – | |

| 316 | ≥ 520 | ≥ 205 | ≥ 40 | ≤ 187 | ≤ 90 | Excellent |

| 304 | ≥ 515 | ≥ 205 | ≥ 40 | ≤ 201 | ≤ 92 | High |

| 430 | ≥ 450 | ≥ 205 | ≥ 22 | ≤ 183 | ≤ 89 | Low |

| 202 | ≥ 620 | ≥ 260 | ≥ 40 | ≤ 241 | – | Medium |

| 201 | ≥ 655 | ≥ 310 | ≥ 40 | ≤ 241 | 100 | Medium |

Tips:

There is a new material on the market called "stainless iron". The so-called "stainless iron" is refers to the recovered iron, lead and steel that are reprocessed and demagnetized.

For reliable bird control solutions, please Call +86-18203207037 or send us an e-mail to info@bird-spikes.net. We will provide you a specific solution according to the actual installation conditions.